Steel, immensely benefitting PEB systems

Moonwalk Infraprojects is a PEB company in Noida and among India’s leading organisations in manufacturing Pre-Engineered Buildings (PEBs) in Steel for prefab Industrial/Factory Buildings, pre-fabricated Warehouses, Girders, Bridges, cold storage facilities, Aircraft Hangars, Metro Stations, Roofs, etc.

A reputed name among pre-engineered building manufacturers in India, Moonwalk has one of the largest plants in Delhi NCR for PEB components manufacturing. It is an expert in manufacturing Custom steel building designs, Prefab steel buildings, Steel building advantages and Pre-fabricated steel components, that it creates using the latest technologies and advanced production processes. It makes primary structures, secondaries and accessories structures, crane systems, mezzanine systems, standing seam roof systems and Hi Rib Roofing &Wall cladding.

From feasibility studies to designing and fabricating to managing supply logistics installation, Moonwalk – a PEB manufacturer in Noida, U.P. – is emerging as a one-stop solution for all pre-fabrication needs in steel. A 11-year-old organisation, it has, in a very short span of time, delivered immense projects for notable clients across Government and the private sector.

Steel, becoming integral to development

Steel is slowly emerging from the shadows. It is revolutionising our world and contemporary living seems impossible without it. Steel is now the preferred building material for skyscrapers, railway stations and an array of infrastructure projects. It’s time to capitalise on existing capabilities, realise steel’s immense potential and enable fostering a competitive steel hub in India.

How steel is shining

India is on the road to be a USD 5-Trillion and the world’s 3rd largest economy soon. There is a mammoth scope for infrastructural development, and steel offers an unparalleled array of advantages over other materials.

Decision makers, infrastructure planners and the steel industry needs to come together towards promoting versatile, sustainable and cost-effective steel solutions and increase per capita consumption of steel.

The wonder metal in construction

|

PEBs, leading a quality transformation in steel

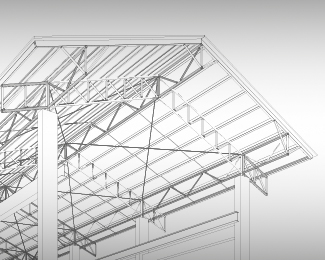

Pre-engineered Buildings (PEB) and steel structures are revolutionising the commercial and industrial construction landscape. Constructed with pre-fabricated components that are manufactured off-site, and thereafter assembled on-site, they offer significant advantages over conventional buildings in steel.

| An immensely

viable solution Architectural versatility Seismic resistant Turnkey solutions Consistent superior quality Reduction in project costs Savings in construction times Suitability for varied projects Flexibility in load bearing Low maintenance Energy efficiency Low-cost constructions |

Rising above conventional steel buildings

| Parameters | Conventional Steel Buildings | Moonwalk’s Pre-Engineered Buildings in steel |

| Structure & Weight | Primary steel members are selected from standard hot rolled ‘I’ Sections, which are, in main segments of the members heavier than what is actually required. | Our pre-engineered buildings are, on an average, lighter due to our efficient use of steel. |

| Design | Each conventional steel structure is designed from scratch by the consultant, with fewer design aids available to the engineer. | Quick & Efficient: Since our PEBs are mainly formed of standard sections and connections, our design time is significantly reduced. |

| Delivery | Around 20 to 26 weeks | We offer DBT guarantee |

| Erection Costs & Time | Conventional steel buildings are 20% more expensive than PEB. In most cases, the erections cost and time are not estimated accurately. | Our costs and time of erection are accurately mentioned, based upon extensive experience with similar buildings. |

| Seismic Resistance | Rigid heavyweight structures do not perform well in seismic zones. | Our low-weight flexible frames offer higher resistance to seismic forces. |

| Building Accessories | Every project requires special design for accessories and special sourcing for each item. Flashing and trims have to be uniquely designed & fabricated. | Our structures are designed to fit the system with standardised and inter- changeable parts, including pre-designed flashing and trims, building accessories which are mass produced for economy and are available with the building. |

| Overall price | Higher price, per Sqm. | Our price per Sqm. may be much lower than conventional steel. |

| Safety & Responsibility | Multiple responsibilities can result in confusion when components do not fit properly. | Since we are a single source of supply results, we assume total responsibility. |

| Performance | Components are custom-designed for a specific application on a specific job. Design and detailing errors are possible when assembling of diverse components into unique buildings. | All our components are specified and designed specially to act together as a system for maximum efficiency, precise fit and peak performance in the field. |

| Fire Resistance | Practically no fire resistance. | Fire resistance can be achieved |

Playing a stellar role in PEB steel structures

Pre-engineered Buildings (PEB) in steel are revolutionising the commercial and industrial construction landscape. From feasibility studies to designing and creating to overseeing supply logistics to installation, Moonwalk Infraprojects is steadily making its mark as a one-stop solution for all pre-fabrication needs in steel.